Mobile High-Pressure Cleaner

Mobile High-Pressure Cleaner

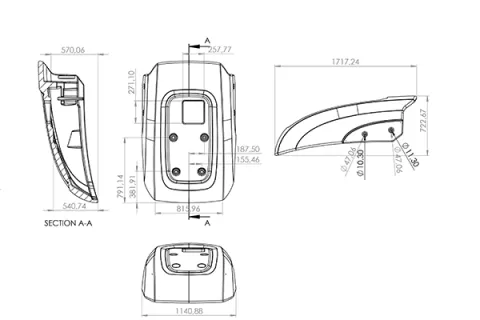

For this application, we designed an innovative chassis with a dual function: it not only forms the supporting structure of the trailer but also serves as an integrated water tank. A clever solution that optimizes weight and space utilization.

The complex design made rotational molding the only feasible production technique. Thanks to this method, we were able to create hollow parts with uniform wall thickness and high structural strength. The aluminum mold was specially designed with multiple removable parts and deep cavities, formed via venturi systems — a technological masterpiece.

For this project, we produced several parts via rotational molding, including:

- The integrated water tank/chassis

- A fender

- A protective cover

- A diesel tank (with ring, locking ring, and lockable fuel cap)

A striking detail is the overmolded hinge in the protective cover. By molding this hinge as part of the lid, we create a unique and durable whole without extra assembly or fastening points — a fine illustration of what is possible with thoughtful rotational molding.